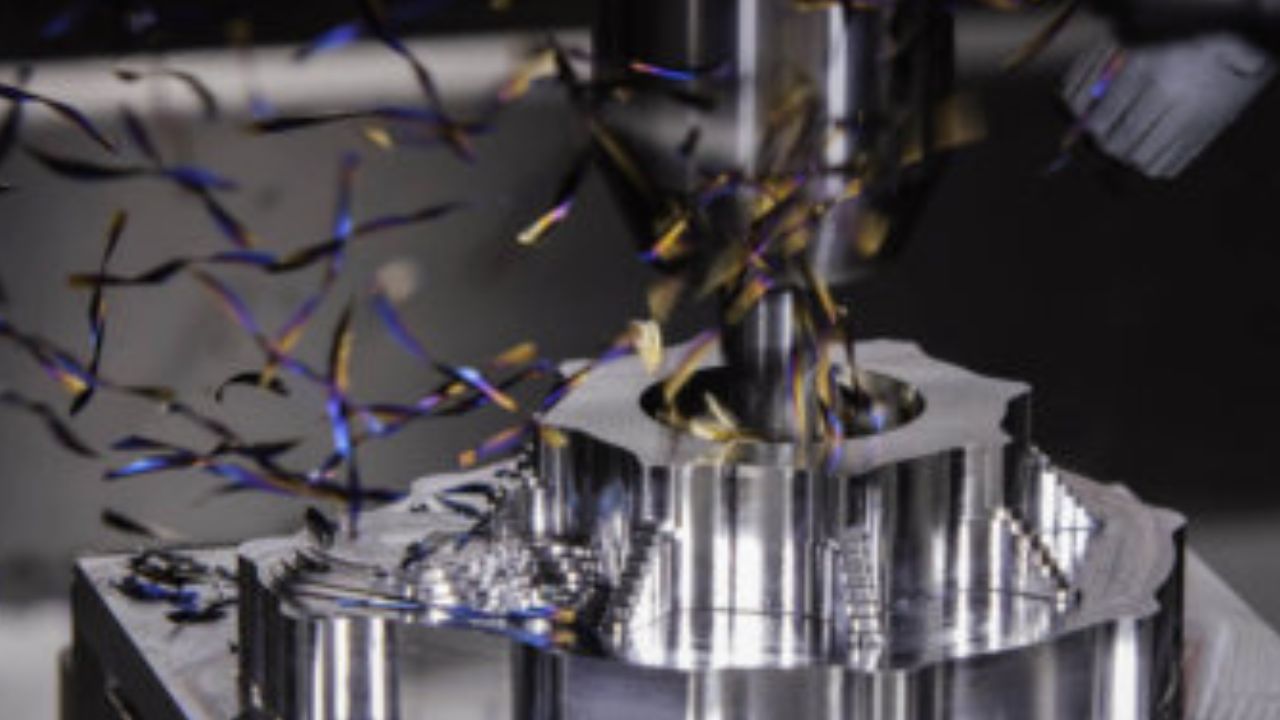

Manufacturing is revolutionized by computerized precision machining or CNC machining. With unmatched accuracy, these machines precisely cut, sculpt, and shape materials using G-code and programmed instructions. CNC machining is essential for producing components consistently and efficiently in a variety of industries, including aerospace and automotive.

CNC machines are utilized to cut, shape, or carve materials with exceptional accuracy. what is CNC machining Computer Numerical Control (CNC) machining is a manufacturing process in which automated machines are designed to perform exacting movements and operations on materials like plastic, metal, and wood. Are 3D Designs Compatible With CNC Machines?

It is possible to use 3D designs with CNC machining. Utilizing a 3D model as a source of information, the CNC (Computer Numerical Control) machine removes material from a block or sheet to produce a physical object. In order for the CNC machine to carry out the required machining operations, the 3D design is normally produced using CAD (Computer-Aided Design) software and converted into G-code.

Materials Can Be Machined With a CNC Machine

When using CNC machining, a variety of materials can be used, such as:

Stainless Steel

Today’s market offers a wide variety of stainless steel alloys. For CNC machining, the grades 304, 316, 416, and 17-4 PH are frequently used. Stainless steels are robust materials that are appropriate for harsh environments because they naturally have a protective oxide layer.

The components that make up the alloying of stainless steel cause the grades to differ. For instance, 316 stainless steel is more resistant to corrosion when molybdenum is added. 303 stainless steel’s machinability is enhanced by sulfur.

Aluminum

Due to its superior machinability, lightweight nature, strength, and extreme corrosion resistance, aluminum is a great material choice for CNC-machined components. Aluminum alloys are suitable for use in electronics and thermal management because they are also reasonably electrically and thermally conductive.

Consideration should be given to weight and application in addition to the cost of materials when deciding whether stainless steel or aluminum is a better fit for CNC machining. Due to its lighter weight, aluminum is the better material to choose when weight is a factor.

Titanium

Numerous industries have seen revolutions thanks to titanium, which has also solved some of the manufacturing sector’s most pressing problems. Alloys made of titanium are robust, resilient, reasonably light, and resistant to corrosion.

Titanium is regarded as the noblest metal and performs exceptionally well in harsh conditions where other metals cannot. Once titanium was found to be biocompatible, the medical field jumped right in and started using it. These days, titanium alloys are frequently used in implantable components and medical equipment, such as screws or devices.

Copper

Excellent thermal and electrical conductivity can be found in copper. Silver is the only metal that works better than copper in thermal or electrical applications. Pure (about 99% commercially pure) copper is very ductile and malleable at lower temperatures, making it challenging for CNC machines. However, there are numerous copper alloys with similar, if not better, thermal and electrical properties that are relatively simple to CNC machines.

Brass

Brass is an alloy made of copper and zinc, so it shares some characteristics with copper. Brass is machinable and long-lasting. In addition, this alloy has a low coefficient of friction, electrical conductivity, and resistance to corrosion. Brass is adaptable and useful in many fields, such as plumbing, electrical, medicine, and the arts.

Plastics

Polymers make up the majority of the materials in the vast category of synthetic and semi-synthetic materials known as plastics. Excellent plastic components with CNC machining are available in a variety of options. Certain plastics, such as HDPE, are moisture-, electrical-, and chemical-resistant. Nylon is resistant to chemical and friction wear. PEEK is lightweight and impervious to wear, chemicals, and moisture. PEEK can even be used to replace most soft metals in CNC machining applications.

Conclusion

CNC machining is an essential manufacturing process that has many benefits and keeps changing as technology advances. There is a bright future ahead of CNC machining, as a number of trends are influencing its course. It is anticipated that automation and robotics will be important, increasing productivity and lowering human error. Complex parts can be produced using both additive and subtractive processes thanks to integration with additive manufacturing.