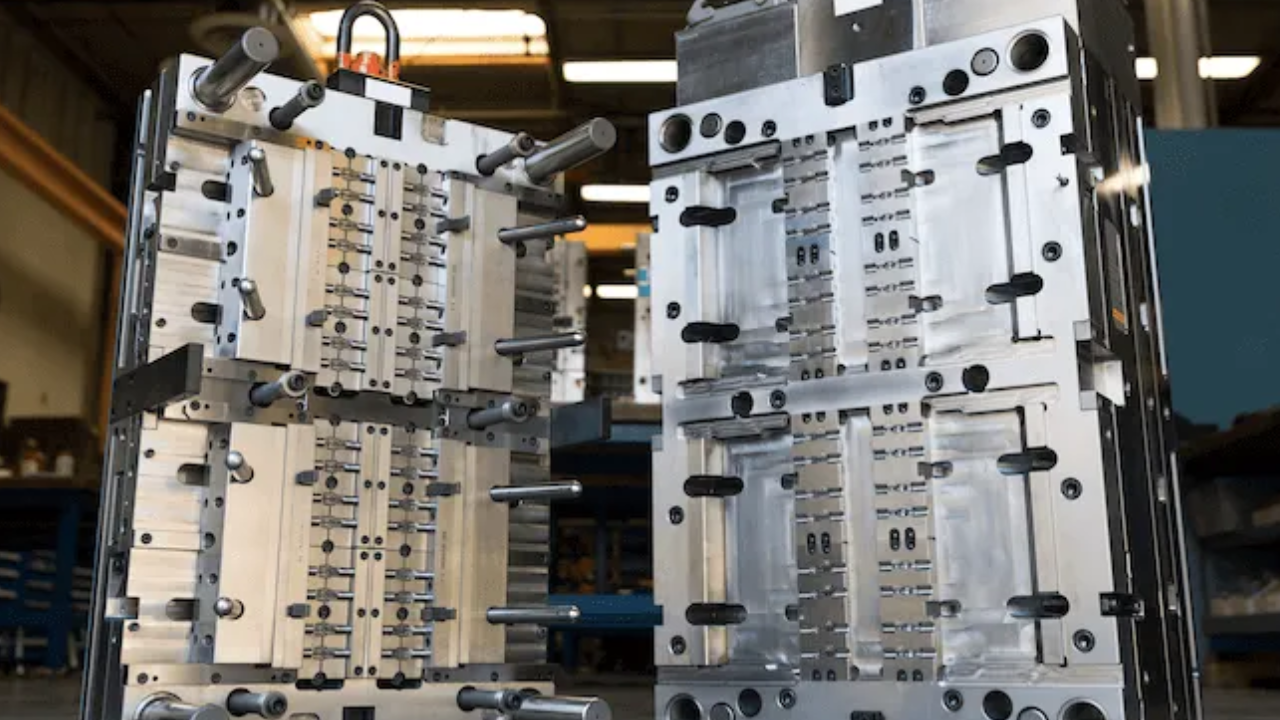

In the fields of manufacturing, construction, and design, molding is the process of forming and shaping materials into a precise shape or object in three dimensions. It has several uses, from producing intricate replicas of parts, items, or artistic creations to augmenting the visual attractiveness of architectural environments. A variety of methods, such as casting, carving, or pressing materials into molds composed of rubber, plastic, or metal, are used to accomplish molding.

These molds https://www.kemalmfg.com/mold-manufacturing-2/ are essential for reproducing complex designs, guaranteeing consistency in manufacturing, and incorporating ornamental or utilitarian components into a wide range of industries, including consumer goods manufacture, engineering, architecture, and the arts. Molding is an adaptable and essential procedure that blends technology and artistry into the physical world around us.

How Much Time Does It Take To Manufacture A Plastic Injection Mold?

The typical lead time for a prototype mold with one cavity is three to four weeks. This estimate works well with a modest cooling circuit, a few minimal ejector pins, and a low manufacturing volume of roughly 450 to 1000 samples.

However, injection into many cavities or more complicated molds may require up to six months to complete. Higher production volumes, ranging from 100,000 to 1,000,000 injection molded components, multiple cooling channels, multiple actions, such as lifters and sliding cams, and complex ejection mechanisms are common features of more sophisticated molds.

Additional variables contributing to extend lead times may include the type of feed system, such as a hot manifold with several nozzles, a high surface finish, and stringent dimensional requirements. Purchasing specialty parts like hot runner systems and imported accessories may potentially cause the current timeline to be extended.

Material Utilized to Create Molds

Budgetary restrictions, manufacturing volume, material type to be molded, and intended usage all influence the choice of mold material Common Materials for Mold Design

Metal Compounds:

Steel: One of the most common materials used to create molds is steel. It is renowned for being strong, resistant to high temperatures, and has exceptional wear resistance. P20, H13, and S7 are examples of tool steel that is frequently used for die-casting and injection molding molds. Applications for food and medicine commonly use stainless steel.

Aluminum: Due to its superior heat conductivity and lightweight nature, aluminum molds are preferred. They are frequently employed in low- to medium-volume manufacturing, particularly in plastic injection molding.

Copper due to their outstanding heat conductivity, copper molds are a good choice for procedures requiring quick cooling. They are frequently employed in the manufacturing of confectionary and chocolate goods.

Polymers:

High-Density Polyethylene (HDPE): HDPE is an inexpensive plastic that can be used to make basic molds, such as the ones used for casting concrete. Workability is right, and it has good chemical resistance.

Polyurethane this adaptable substance is utilized to make bendy molds. It’s often used in programs consisting of artistic casting and rubber part molding.

Epoxy Resin epoxy resin molds are utilized in a number of fields, together with electronics, jewelry layout, and the arts. They provide outstanding surface polish and exquisite detail.

Combinations

Fiberglass: Because fiberglass molds are strong and lightweight, they can be used to create parts with intricate geometries. The aerospace, automobile, and boat manufacturing sectors frequently employ them.

Carbon Fiber: The remarkable strength-to-weight ratio of carbon fiber molds is well-known. High-performance industries like motorsports and aerospace find use for them.

Silicone Rubber: Molds made of silicone rubber are renowned for their exceptional releasing qualities and flexibility. They are frequently employed in the creation of elaborate and sophisticated components, such as prototypes and decorative objects.

Conclusion

The choice of materials for mold design is an important one that affects the outcome of many different production and creative activities. Understanding the characteristics and uses of various mold materials is crucial for producing the intended effects quickly and affordably, whether for commercial production or creative projects. Giving careful thought to elements such as material properties, part complexity, and production volume.